Other Names

- Radford’s1

- R Radford and Sons abattoir3

Current Operation

- Currently operating at 16.11.2013

Location

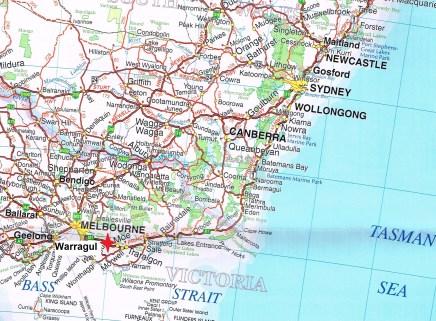

- Warragul is approximately 120km south east of Melbourne.

Hema Maps – Australia Handy map – 9th edition

Hema Maps – Australia Handy map – 9th edition

Owner

- Radford’s1

- Family-owned meat processing business3

- Managing director – Robert Radford1

Operation

- At 2011 processing 120,000 sheep and lambs and 80,000 cattle per year2

- Operate 5 days a week, 52 weeks a year3

- 1,400 cattle and 2,500 lambs a week3

- Currently processing sheep and cattle but looking to process goats in the future5

- Goat processing added after closure of Trafalgar (Giles) abattoir7

- Currently domestic processing 18-21kg carcases boutique markets5

- Process lamb for different domestic cultural and religious festivals5

- lambs need to be very lean 116-18kg5

- Italian community like 18-20kg5

- Vietnamese and Chinese want very lean 20-22kg, no fat5

- Warragul own a retail shop in Kyneton, this has added to tourist trade5

- Export markets

- Middle east require a very lean carcase under 18kg5

- cook meat slowly and too much fat congeals at top of pots5

- Lamb and mutton exported both whole and 6-way cuts, fresh and frozen air freight5

- Middle east require a very lean carcase under 18kg5

- 15% production is certified organic5

- 40-50% growth in organic meat processing in lst 3-5 years5

- Animals sourced all over Victoria, In SA Mt Gambier and Naracoorte, In NSW as far as Gunnedah, at times also Tasmania.3

Source Hema maps – Australia Handy map 9th edition

Source Hema maps – Australia Handy map 9th edition

Figure 1 – showing area from which Warragul abattoir source animals across South east Australia

- Animal Welfare practices3

- animals are stunned with electric stunner, cattle knocked unconcious prior to slaughter3

- Stunning is audited and people are specifically trained for the stunning role3

- Primesafe -Victorian meat authority conduct regular audits at least 3-4 times a year3

- Audits are unannounced inspections3

- “Focus on animal welfare is critical to the success of an abattoirs relationship to its suppliers and customers” Robert Radford, Manager5

- There are sound business reasons to conduct rules of treatment and slaughter of animals.3

- business can be closed instantly for breaches3

- Plant invested heavily to allow animals to rest prior to slaughter3

- Stock yards are covered in sawdust to soften footing. – then is reused as fertlizer3

- stressed animals create poor quality meat cutting so better welfare is a better animal carcase produced3

- stockyards are undercover and allow 750 cattle to be held.3

- Animals allowed up to 48 hours rest before slaughter5

- Prediction of meat quality use3

- PH level as indication3

- hanging method of carcase is tender stretching and not hung from achilles3

- Resources used3

- water was a major problem in the drought – using 100,000 litres per day,3

- not connected to mains water and had no access to ground water3

- developed a recycling of own effluent waste3

- developed with help of governmentm cost $1.1M3

- water was a major problem in the drought – using 100,000 litres per day,3

- Products

- skins – are all sold as tenders to various markets and graded to their quality3

- skins often to China – car seat covers, shoe lining, clothing5

- Offal and other byproducts are value added, producing tallow and meat meal5

- skins – are all sold as tenders to various markets and graded to their quality3

- Business

- need to constantly look at Research and development to consider productivity, running costs and new technology to increase through-put3

- Looking to enter Halal export markets5

- Domestic Halal is common, enables offal byproducts to be sold for human consumption5

- Only some victoria abattoirs allowed to do Kosher processing5

- Slaughter process

- Last 20 years focus is meat processing and wholesalers5

- After each kill – meat buyers mark up (rate) bodies at 5am each morning, looking at quality and matching to orders4

- Average 120 bodies – 60 will get top money, 30 OK, 15 barely cover costs and 15 probably lose money due to bruising or cutting dark4

- “You’ll get your money on 50% of the beef bodies, the next 20-30% you’ll make a bit on, and the rest you’ll go backwards by about $40 to $50 a body” Danny Hood – Meat Wholesaler4

- Being a perishable item, aim is to have the kill sold and placed within 7 days4

- Price spread across beef bodies of 100c/kg carcass weight4

- Domestic to wholesaler mark up is approximately 50-70c/kg4

- 200kg carcase from abattoir has markup about $140 by wholesaler to cover transport, processing fees and delivery charges.4

- Employees

- Warragul employees average 10 years of continuous service6

- In 60 years of trading not lost a single day to industrial disputes6

- All employees require Certificate 2 status in food processing6

History

1944

- Father began business as one-man slaughterhouse

- on-man slaughterhouses were in most towns, Warragul had 6.

1946

- Radfords – Warragul established6

2007

- Involved in delegation of 200 Victorian food manufacturers to develop worlds first global halal brand, invited by the Brunei government.1

- Note from Managing director R Radford and Son – 28/02/2014 – Radfords were a participant in the delegation to Brunei, any publications stating or implying that R Radford and Son process meat for halal markets are incorrect. R Radford and Son do not and have never processed meat for halal markets and have not sought accreditation.1

2011

- Won awards2

- NAB agribusiness leader of the year2

- In past decade Warragul have doubled processing to 80,000 cattle and 120,000 sheep and lambs a year.2

- Environment and Energy management2

- Reduced consumption of electricity by 4.17%2

- Reduced gas consumption by 30.5%2

- Reduced fuel use by 19.2%2

- Reduced water use by 44.5%2

2012

- NAB agribusiness leader of the year2

- Up to 2012 had invested $8.3M in new plant. equipment and supporting infrastructure

Sources

- ‘Victorians work on first global halal brand’ The Age 24.09.2007

- ‘Abattoir leads way’ Pakenham Gazette star community 07.12.2011

- ‘A cut above’ ABC Landline 21.10.13.

- ‘Story behind beef retail prices’ Weekly Times 10.10.2013

- ‘Abattoirs cater to emerging markets’ Stock Journal 26.09.2013

- http://www.radfordmeats.com

- Inquiry into the impact of food safety regulation on farms and other business 18.10.12.

- Personnal Communication. R Radford. 28.02.2014