Australian Agriculture Company (AACo) is Australia’s largest beef producer owning in excess of 500,000 head. The building of the Livingstone beef processing facility near Darwin is the first new cattle abattoir to be built in Northern Australia for 50 years. It is the first operational beef export accredited facility operated in the NT for nearly 15 years. Currently mothballed after 3 years of operation.

Current Operation

- Livingstone abattoir, Was announced to be mothballed in September 2018.125

- Ausmeat Accredited #80073 (as of February 2015)

- Export Abattoir for Beef /Offal.73

Location

- 50km S Darwin, 600 ha lot, 14ha buildings, rest area used for irrigation, wetlands, ponds and buffer zone.

Owner

- AACo, looking for partnership with overseas investor

- AACo intend to always retain 50% ownership. (AAco own 485000 cattle – will supply 50000 hd through its own Northern supply company)

Historical and current meatworks, canneries and abattoirs located in Australia can be viewed at;

Australian abattoirs inactive map

Operation

- Initially Stage One – 100,000 head capacity with development through modular construction

- 1,100 head a day, flexability to incorporate carcase chillers when required

- double shift platform 7 months of year, single shift for another month and closed during wet15.

- Work 11 months of year atleast 5 days a week

- slaughter grids HSCW c/kg

- inject $126M into economy6

- Day care facilities7

- Medical facilities to assist with Workers compensation costs7.

- Darwin site chosen – just 50km from international seaport for exporting meat to key Asian markets. close to Major city to attract and retain workers and other support services for the proposed facility, with other benefits in AW , transport and carbon benefits12

- Will be hot boning room (Stage 1 low cost production model), chillers and full capacity if fully developed to 225,000 head year.

- Refrigeration system – one of the most technical and energy efficent installed.58

- Built by one of the largest industrial refrigeration providers in Australia, Gordon Brothers Industries58

- Cascade system – Refrigeration is in two parts58

- Low temperature side operates on Co2 as the refrigerant58

- High temperature side operates on ammonia.58

- Designed to allow for future expansion58

- Market for cull animals cows and bulls and heavier slaughter weights steers, types unsuited to Live export Indonesia (feeder steers under 350kg)

- complementing Live export not replacing it

- Meat exported via Darwin Port to US, Asia including Indonesia, China and Philippines

- 260 direct and further 530 indirect jobs.

- Capital injection of $126M a year

- Will be most carbon efficient plant in Australia, Claims will save 6M truck kilometres by reducing 30% truck requirement to east coast, cattle processed in Darwin expected to fetch premium of $42/hd above existing meat supply chains15

- IAR – Individual animal recording will be used for management system5

- ACIL Tasman Report – found a main benefit the proposed AAco abattoir would be providing a market for excess cast for age female cattle and as a result would promote productivity improvement in breeding herds.8

- Facility is Halal accredited111

History of the Livingstone meat processing facility

Source – AACo Handout. Katherine Dec 2012.

Source – AACo Handout. Katherine Dec 2012.

Proposed location of AACo abattoir near Darwin comparative to existing 35 largest beef processing facilities in Australia at the time.

2010

- July. AACo seeking investors to back its proposed top-end works capable of processing 140,000 per year38

- Estimates – $35M + $12.5M, If have government support up and running April 201211

- Estimate $81M to construct (paper 06.06.12), Fed gov haven’t supplied funding as yet (Jan 2013) to project1.

- Requires another $25M by Fed Government for road re-alignment, power, water, gas, rail, ports, Project not funded in 12/13 NT budget7.

- Currently one container ship per fortnight is loaded Darwin, Abattoir will require 2 container ships a week to take supply7.

- Requires 145 container points at Port of Darwin15

- Estimate $85 to construct (AACo board 19.10.12)

- AACo – Wholesale Beef Group – sold 16,900t boxed beef in 2012, 17,000t in 20115

- Korea – AACo’s largest export market for boxed beef, 20% of annual beef sales16

- LE ban cost AACo $51.2M16, due mainly to land valuation write downs.

- Managing director at this time – David Farley.137

- Led AACo between 2009 to 2013137

Source Northern Beef Limited Phamplet.

Artist impression of built Livingstone abattoir

- August. Idea put to producers in NT to build abattoir14

- AACo launch a feasibility study.54

- facility could take 2 years to build.54

- AACo believes a northern abattoir could play a key role to allow it become an integrated producer, processor and marketer.54

- Indonesian weight import restrictions of animals being required to be less than 350kg had affected AACo, who sold 90% of export animals to Indonesia.54

- October. Looking for support to build abattoir11

- Problems anticipated – Labour and housing costs11

2011

- AACo raise $60M from Institutional investors and hopes to raise another $30 from ordinary shareholders39

- AACo expected to peak this year with ownership of 640,000 cattle39

- July. AAco sell a QLD property – Meteor Downs $21.6M (17,474ha), south of Emerald.53

- AACo will consider sales and purchases to re-aling its footprint in North Australia53

- Hoped Planning approval would occur by Christmas 201153

- two sites being considered for the facility53

- construction is expected to take 12 months, employ about 150-180 staff.53

- Mr David Farley Managing director of AACo, says the facility is not an alternative to live export.53

- ‘If we had to get to that point we’d need $10 billion, a 10-year planning horizon, major investment in roads, rail, port and electricity – and 10 good men to oversee getting the job done, You’d need to process about a million cattle a year in northern Australia if you want to replace Live export” David Farley53

2012

- Environmental assessment report conducted. “..there were significant uncertainties that had not been adequately dealt with…these relate primarily to the management of waste water and the need for effective management of odour, noise and dust“76

- February. Plant estimated to cost $80M,

- Plan to be in opertion at around October 201315

- Potential price premiums of $30+ a head from overseas meat buyers wanting to source product from low-carbon production backgrounds15

- International indicators suggest $42/head premiums above existing Australian meat supply chains15

- Process 135,000 cattle per year and require 260 full time staff15

- Staff likely flown in from India and Philippines15

- March. NT Minister for Primary Industries Kon Vatskalis announced at NTCA conference, Darwin $9M to be provided in kind by NT Govt.

- Federal Government had no applications and funding never occured14

- AAco post a financial loss for year ending March $8.4M39

- Cite reasons for loss “Primarily due to flow on effects from the Federal government’s live export suspension of mid-2011″ Don McGauchie, AACo Chairman39

- Continued high dollar39

- AACo now estimate related devaluation of Northern Australian properties due to export suspension devalued by $51.2M39

- Implementation of ESCAS is challenging “Australia is the only country to attempt to regulate livestock exports from paddock through to processing in another country” Don McGauchie39

Source – AACo Annual Report ending 2012 (March)

Source – AACo Annual Report ending 2012 (March)

Markets that AACo sell their cattle to.

Source – AACo Annual Report ending 2012 (March)

Source – AACo Annual Report ending 2012 (March)

Cattle sales in percentages compared to full year sales.

- April. Govt support required for highway expansion, port facilities for refrigeration, local health care facilities14

- May. Government give approval to development subject to 5 conditions being met.35

- ACIL Tasman report ACIL_EconomicImpact_AAcoAbattoir – May 2012.

- Capital cost of the plant forecast to be $83M43

- fully operational by 2014 with full throughput capacity 201643

- AAco processing minimum of 35% their own stock.43

- Closest abattoir – Townsville 2000km from Darwin.43

- Proposed abattoir process 179,000 cattle can be modified to 225,000 with minimal capital expenditure.43

- AAco anticipates processing 63,000 of their own stock.43

- Majority of the throughput 80% being cull cows.43

- Modelled on Average liveweight 430kg, dressing to 50% with saleable meat yield of 72% fo the HSCW43

- Capital cost of the plant forecast to be $83M43

-

- Produce 28M kg of saleable beef and 36M kg offal, 6,900 hides43

- No current regional market for cull cows and bulls.43

- development of a cull market will enable younger, more robust, fertile herds reduces mortality and increases calves produced.43

- Returns for cows would improve 117%43

- Depending on capacity of plant and supply of heavy animals could increase sale value of animals in north by 31%43

- Increased investment is required for all weather access.43

- Abattoir would be closed December periods.43

- June. AAco says needs Indian worders to help fill 260 new positions10

- AAco announce they have purchased 600ha site 50km south of Darwin – Livingstone35

- Plant estimated to cost $83M35

- Initially plant to process 185,000 cattle annually, capacity with further development to 225,00035

- AAco to always hold 50% equity in plant35

- Three months to June 2012 – AAco Total cattle sold 68,660 cattle. Av $967/hd21

- Wagyu beef sold 2,487t21

- Short fed grain finish beef sold 1,965t21

- October. Design phase complete, NT Governement has granted various planning approvals7

- Federal funding in last budget wasn’t provided as they hadn’t received a solid proposal49

- AAco board approve commencement of civil and construction works36

- Plant estimated to cost $85M36

- $14.5M spent by AAco on site to date. Earthworks beginning on site5

- RSPCA quoted as saying as soon as Darwin ab opens they will be increasing demands for LE to be shut down8.

- “Federal government committed to promoting economic diversification in Northern Australia”9 Joe Ludwig, Current Minister for Agriculture.

Source -The 600ha site for the AACo abattoir at Livingstone – Photo Carl Curtain.

‘AAco board finally approves Darwin abattoir’ ABC Rural. 19.10.12

2013

- Discussions under way with potential equity partners5

- February. Changes to water treatment process on site from an effluent dam storage treatment and irrigation system to a dissolved air flotation system13

- Preparation of site and civil works well advanced, light wet has been good advantage. Construction phase to begin 11.02.13

- March. 260 staff required – will use 457 visas16

- Government threatened to impose further restrictions on 457’s, “ if you want to delay, disrupt or waste Australia’s future then the 457 actions of the Gillard government will do all of that” – David Farley. AACo CEO16

- April. Completion of first stage of construction17

- Speculation development may be abandoned40

- AACo say waiting for equipment to arrive.40

- AACo announce selling two QLD properties40

- Northern Territory Treasurer – Country Liberal Government, “There is no money available to support the abattoir” David Tollner, Minister for Business41

- May. Construction expected to recommence late May17

- AACo now sourcing capital to finance the abattoir without private investors17

- Estimates of build now $85M17

- Uncertainty of government funding and private joint ventures led AACo to fund project independently17

- June. Three months to June Financials for AACo.21

- AACo cattle sales – Total Sold 99,654 cattle, Av $676/hd21

- Grass fed/finished 28,275 hd21

- Breeder and Feeder Cattle 37,456 hd21

- Live export 20,14621

- Wagyu 8970 hd21

- Previous year same period – Total sold 68,660 cattle, Av $967/hd21

- AAco wholesale beef business21

- 2140t Wagyu21

- Previous year same period 2,487t Wagyu21

- Short fed – grain finish 1,699t21

- Previous year same period 1,965t21

- 2140t Wagyu21

- AACo cattle sales – Total Sold 99,654 cattle, Av $676/hd21

- August. AAco CEO David Farley is dismissed18

- Farley had served AAco for 3 years and 8 months20

- “..investing in a Darwin abattoir was important strategy to break reliance on large-scale processing competition in Australia, while also protecting the value of AAco’s northern beef properties” Nick Burton Director & Chairman of AAco, commenting on how Farley had helped to reposition AAco through difficult periods.18

- Concerns are raised that abattoir won’t be built without Farley but at AGM Chairman Donald McGauchie the board has given full approval for the project.28

- AAco recently sold Brighton property $11.5M18

- part of strategy to focus capital in North Australia18

- Finance of the abattoir had caused friction in last 2 years18

- AAco may need to raise $150M in fresh equity to get its debts in order19

- currently hold 1% of Australia’s landmass19

- 600,000 cattle across 7.2M hectares.26

- Australia’s biggest beef producer26

- has Gross debt $423M at March 31.2013.19

- recently sold properties worth combined – $25M19

- AAco’s current debt to equity is 70%19

- Ideally would be 30%19

- Current major stakeholders – Wellington Management cut its holding from 8.1% to 6.5%19

- Biggest shareholder Malaysia’s Felda Holdings and IFFCO failed to participate in 2011 revenue raising19

- Tavistock Group, investment company of Britishman Joe Lewis owns 11% of AAco21

- global beef prices are hovering near 3 decade low19

- Due to poor wet season and low live export orders19

- currently hold 1% of Australia’s landmass19

- AAco current share price – $1.09c20

- Meatworks due to be completed first half of 2014.20

- Livingstone abattoir now estimated to cost $91M21

- September. AAco shares are placed on trading holt.22

- AAco announces it wants to raise $299M in capital through a share offer22

- Share offer to be $219.2M fully underwritten 7 for 10 accelerated non-renouncable entitlement offer.22

- $80M subordinated convertible notes maturing September 2023.22

- Capital raising to be used to reduce Net debt from $412M of predominantly secured bank loans to $248M, including the $80M convertible notes.42

- Gearing will fall from 40.9% to 23.5%42

- Funds to be used to “support a future refinancing of its existing facilities”22

- Within 2 days of announcement large investors generate $129.2M23

- Existing institutional shareholders took up 56% of entitlements23

- In effort to cut costs AAco move Brisbane headquarters to Fortitude valley consolidating two locations into one.23

- Abattoir now stated to have future processing capacity of 200,000 hd22

- Half year Financial results – End of September 2013 AAco report after tax loss of $31.6M26

- Cattle liveweights fell 12% contributed $20.4M to fall in revenue26

- Total revenue fell $15.6M to $177.7M26

- cite reasons for loss as ongoing effects of June 2011 suspension of live exports27

- below-average seasonal rainfall in North Australia27

- some properties recorded lowest rains on record27

- comparisons of earnings to previous years same period27

- Sept 2013 – delivered 172,517 hd for sale27

- Sept 2012 – $147,693 hd for sale27

- Sept 2013 – Average $731/hd, 20% lower than previous period27

- Sept 2012 – $919 /hd27

- Sept 2013 – Cattle purchases 14,453 hd27

- Sept 2012 – 61,181 hd27

- Sept 2013 – Kilograms produced 44.7M kg27

- Sept 2012 57.7M kg27

- Authors Note Kilograms produced is a benchmarking technique taking into account animals born/deaths and differences in weights of sale animals to previous year. It is not simply sale animals weights.

- Sept 2013 – delivered 172,517 hd for sale27

Source – ‘AAco rules out split, plans $299M raising to expand to Asia’ The Australian 13.09.2013

Source – ‘AAco rules out split, plans $299M raising to expand to Asia’ The Australian 13.09.2013

Global beef price v’s domestic cattle prices / AAco revenue contribution.

- October. Tavistock Group – owns AA trust – operated by Joe Lewis – Discloses 19.9% in AACo.24

- has purchased an extra 1.8% – derivative contract.24

- 20% threshold ASIC – take consideration as formal takeover – 1.8% not physical ownership therefore ASIC/take over panel not concerned.24

- Bonds of 8% due to convert at fixed price $1.15 will allow Lewis ownership of close to 30% AACo.24

- has purchased an extra 1.8% – derivative contract.24

- AA Trust. Is Bahama based. Is a stable company of Tavistock Group100

- Lewis could command up to 30% of AACo’s register by September 2014.100

- Larger foreign shareholders are rumoured to want split the company in two.100

- Rumours were dismissed with investor said to favour the transformation of AACo into a pure meat processor and exporter to Asia.100

- AACo purchase 2 NT properties – Labelle Downs and Welltree Station – $27.1M25

- No cattle included in sale, only plant and equipment25

- RM Williams had previously owned properties – gone into receivorship25

- Properties were 180km from Darwin and complement abattoir25

- ensure continuity of supply of animals through both wet and dry season.25

- AACo retail component of $299M capital raising is successfully completed97

- Retail Shareholders subscribing to $46.1M in shares97

- Institutional offer and convertible notes issuance had been completed in the previous month97

- Livingstone abattoir is expected to be completed second half of 201497

- Processing capacity of over 200,000 per annum97

- AACo appoint contractor Milmeq (New Zealand based) – build refrigeration and food processing equipment in abattoir – worth $21.4M29

- Were not able to find anyone in Australia who were able to give full turn-key operations29

- Milmeq have subcontracted to an Australian based refrigeration company some of the tender.29

- Haarslev – Denmark company won $6.5M contract to build rendering and waste treatment plant29

- Managing contractor – Sunbuild – has sub-contracted much of the construction work to local companies.29

- NT Country Liberals Government has enabled removal of red tape to allow agreements that suited both sides better than in the past.29

- November. AACo report a net loss after tax of $31.6M in first half year results98

- Domestic cattle prices had slumped – decline of 12%98

- On-going effects of Federal governments June 2011 Live export ban98

- Below average seasonal northern rainfall98

- Domestic cattle prices had slumped – decline of 12%98

- Acting Chief executive officer currently – Craig White98

- New Livingstone facility would be crucial to enhancing the group’s profits and well as reducing volatility of the groups earning profile98

- Lewis – Tavistock Group own almost 20% of AACo99

- Rumours Joe Lewis wants to break the company apart99

- Tavistock were the primary backer of the capital raising99

- December. Facility is based on similar layout to Hunter Valley (EC Throsby – NSW)37 (Not yet added to blog)

2014

- January. AAco investigate options to enable supply of employees30

- Providing work for prisoners – Sentenced to a job program30

- Prisoners would get minimum wages after being trained.30

- Money would be held by the Territory to pay for their board.30

- Enables training to devleope skills and then move to full time work before they leave prison30

- Require 350 workers30

- locals get priority.30

- Nik Taylor – Associate professor – Flinders university says using prisonersto work in the Abattoir would be “psychologically damaging”31

- “We’re asking people to take lives from sentient creatures”, “Theres lots of other work that doesn’t have the kind of moral ambiguity we have around slaughterhouses” – Nik Taylor31

- Nik Taylor studies links between domestic abuse, child abuse and violence to companion animals32

- Taylor is an associate of New Zealand Centre for Human-animal studies -“whose research is concerned with the conceptual and material treatment of nonhuman animals in culture, society and history”.34

- She is also a committee member of ‘Minding Animals Australia’ – Minding Animals International state their main objective as “… to further the development of nonhuman animal studies internationally and to help establish legal and moral protections for nonhuman animals”33

- Authors Note – At time of writing Karnet abattoir (WA) is a low security prison operated abattoir located in Western Australia

- Providing work for prisoners – Sentenced to a job program30

- Jason Strong is appointed managing director and chief executive officer, was previously the companies general manager44

- February. Organic farmers in the NT express and interest in buying meat meal from the plant45

Source – ‘Darwin abbatoir on track for AACo’ ABC Rural. 20.02.2014. Photo Jeanette Button

Source – ‘Darwin abbatoir on track for AACo’ ABC Rural. 20.02.2014. Photo Jeanette Button

Construction of the freezing section. Main building for processing of carcasses not yet constructed.

More photos of the site are available on the above link

- March. Positions available for application at facility – Number of openings currently 100.

- Construction well under way with expectation of being operation by second half of 201446

- Plant now estimated to have cost $90M47

“We strongly believe that in conjunction with the live export trade this facility will help to improve the overall performance of the Northern Territory beef industry” Mr Donald McGauchie, AAco Chairman47

- AAco confident of securing cattle throughput to keep the plant viable47

- Throughput would start at 300 head a day47

- APA Group – Natural gas supplier announce arrangement of delivery of natural to facility47

- Gas will be sourced from Amadeus Basin (Alice Springs) arrive via APA existing pipeline and a new 2.8km lateral line.47

- New gas line and receiving facility will be owned and operated by Northern Beef Australia Beef Limited – a wholly owned subsidiary of AAco.47

- 10 year agreement with APA group51

- Abattoir will utilitse cogeneration – using both electricity and thermal heating for meat processing.47

- Facility will have capacity to kill 240,360 and 520 head per shift48

- 1000 head per day using 2 shifts per day51

- Carcass breakdown – collection of red and green offals, renderable products to tallows, meat and bone meal. Dry blood and hide processing to ready for further processing off site.48

- Hot Boning – Will be conducted in Stage 1 of manufacture with stage 2 being cold boning if further developments are made in the future.48

- Animal is expected to be processed within 24 hours of delivery48

- All animals pre-slaughter electrically stunned48

- From time of stunning to time meat enters freezers – 45 minutes48

- Facility will have capacity to process buffalo48

- Cattle will be paid on HSCW (Hot standard carcass weight), manufacturing cattle will have a set price and grid prices for prime.48

- Online portal for feedback to suppliers to be developed.48

Source ‘AACo abattoir set for spring start’ The Land 28.03.14

Site Construction at the site in March 2014. The Packing label is slightly wrong and should be more to the right

- Plant now cost more than $90M, expected to begin operations in September 201450

- Processing will start at 300 head a day before steadily increasing50

- Refrigertion and rendering equipment is now arriving and being installed.51

- Expected savings of transport of stock from Katherine or the Victoria river area to a QLD plant will be $160 per head or $20,000 a trip48

- Some within Australia’s established processing industry rate the plant’s chance of long-term success at zero63

- Plant will contribute more than $120M to the local economy63

- AACo 2014 report – The Northern Beef Processing Facility will be complementary to AACo’s live export trade, not a competitor, providing a market channel for cattle not destined for live export. (Pg 11)69

- AACo, current Australian herd (including animals in feedlots and calves) 552,065 at 31/03/2014 (Pg 95)69

- At 31/03/2013 was 677,217.(Pg 95)69

- sales occured due to dry conditions necessitated de-stocking across the industry, forcing domestic cattle prices lower (Pg 8)69

- company has destocked significantly past 18 months due to drought mitigation measures74

- core breeding herd of 185,000 head74

- Currently running 467,000 head of cattle across 7M hectares74

- AACo’s branded beef division increased 329% to $17M gross profit.74

- Net loss after tax of $40M for the year to March 31.74

- Abattoir is on track to opening in September 201474

- May. Author – Blog article I wrote after viewing AACo Beef Processing facility

Source Jo Bloomfield. Livingstone abattoir site at March 2014

Source Jo Bloomfield. Livingstone abattoir site at March 2014

- May. Showcasing product representation through a trial run dummy kill at a QLD export plant.52

- Brisbane based branded beef group to be responsible for management of sales out of Darwin plant.52

- Showcasing allows confidence and security around stable pricing out of Darwin plant.52

- Some of the product went to China52

- Plant expected to be opened September 2014.52

-

- First time slaughter facility has returned to NT on commercial scale since closure of Katherine (NT)52

-

- Initial costs in establishing the plant with disproportionate operating expense in first year of set up, on completion management of budget is confident by AACo.52

-

- Cattle supply secured from start September to End March 201552

- Some of AACo’s own stock52

- Some cattle purchased by AACo to hold for slaughter52

- Supply agreements locked in with other livestock Northern producers52

- Initial start up will be half-shift daily – represents 50,000 head cattle a year.52

- Depending on operating conditions, issues of start up improve will progress to52

- full shift – 110,000 per year52

- 2 shifts – 220,000 per year52

- Depending on operating conditions, issues of start up improve will progress to52

- June.

Source – Photo supplied by AACo. June 2014

Source – Photo supplied by AACo. June 2014

Showing Livingstone beef processing facility near completion.

- July. Abattoir is currently at 80% capacity101

- August. AAco is no longer a cattle company – it’s a beef company.55

- Vertical integration from production, processing, sales and marketing.55

- closed system to maximise profits.101

- Transition has been happening for several years.55

- Over 12 years the branded beef has grown from nothing to a division that provides half the companies revenue.55

- Top Wagyu brands selling for more than $250 /kg55

- Asia is the main target market for AACo’s production.55

- Testing is occurring at the plant, securing of some accreditations was still ongoing, Ausmeat, AQIS, USDA and market access accreditations.56

- ‘Preferred supplier status’ where suppliers who are able to supply in the wet seasons may be given space for kills in the dry, co-ordination by AACo with other producers.56

- AAco are stocking Labelle Downs and Welltree proeprties so as to supply facility over the wet season.57

- Manager from Eva Downs on the Barkly – Tim Milne.57

- Many came from AACo’s own properties at VRD and on the Barkly57

- One third of the herd is cows for processing at Livingstone57

- Two thirds are shipper types for live export57

- AACo have also purchased the Pell Airstrip and Tortilla blocks to enable supply of cattle incase the roads are out to Labelle and Welltree57

- $8M to buy Pell Airstrip & Tortilla67

- NT prisoners helping to construct the cattle yards at Livingstone.74

- Correctional Services won a contract to supply workers74

- Ahead of a Chinese company74

- 40 prisoners on project for up to 3 months74

- Enables prisoners to learn skills74

- Prisoners pay board, lodgings, pay tax and pay a levy to victims of crime74

- Correctional Services won a contract to supply workers74

SEPTEMBER 2014 – LIVINGSTONE BEEF PROCESSING FACILITY IS OFFICIALLY COMMISSIONED59

- Begins processing of manufacturing beef to supply Asia, United States and European Markets.59>

- Initially the plant will only process AACo stock59

- Expects to process other clients early 201559

- Will give the live export dependent northern beef industry a fresh option for stock that don’t fit export specifications.59

- Other areas are watching to see if the abattoir benefits economics of beef production to enable hastening of plans for others.59

- Northbeef project59

- One shift is operating at present employing 160 people, processing 520 head a day59

- Capable of operating 2 shifts, nominal throughput of 220,000 head a year.59

- At full capacity turn off will be 25 containers a week of frozen and chilled beef, along with hides, offal and tallow.59

- 85 people currently employed, killing small numbers of cattle but only for training and trial purposes76

- 90% of employees are local76

- Facility has to meet standards of an Operational Environmental Management Plan (OEMP) before a licence to operate can be released.76

- October. NT Environmental protection Authority has concerns with companies management of waste water, noise, odour and dust.60

- EPA held back commissioning of the facility.60

- Taken AACo over 5 years to get the facility built and operational60

- 85 workers already employed60

- Eventual cost of facility $91M60

- Plant was close to signing off on requirements around operation and licensing61

- Next major goal is have staff trained to conduct a single shift of cattle by March 2015.61

- Already have 43,000 cattle lined up and dedicated to the plant to March.61

- building up to a single shift will involve a progressive ramp up of supply, training, people and operations.61

OCTOBER 31, 2014 THE LIVINGSTONE PLANT CAN LEGALLY START TO OPERATE.62

- EPA deliver licence to allow start of operations.62

- Detailed bureaucratic process, part is negotiation, part is understanding what the requirements are62

- things had required more detail than AAco had originally thought.62

- No substantive change had to be made to the plant, design or or manufacture.62

- 78 conditions of the environmental licence64

- First of its kind in decades for a new meat processing facility64

- Not unusal for licences to go through multiple stages before final approval64

- Annual review will be conducted to ensure facility meets standards set.62

- First significant abattoir in Northern Australia in 50 years.64

- Previous facility in operation in the NT Katherine #2 (NT)

- At different times the north had 10-12 abattoirs, that processing capacity has vanished. Abattoirs in the NT

- More than 90 abattoirs were lost from Australian agricultural landscape between 1980-200566

- Killing started immediately – 40 head a day, have been able to do that while commissioning.62

- Product will accumulate in cold storage before the first sale is delivered in several weeks.64

- First customer will be un-named domestic manufacturing beef customer on the eastern sea board64

- AACo are not concerned about rising prices of live export cattle62

- “We are quiet aware of that (rising LE prices) and we’ve got to remember that a strong, viable live export industry is good for the plant” Jason Strong. AACo Managing director.62

- Australia’s national cattle herd is set to decline to its lowest level in 20 years

- Forecasts of July 1 2015 Herd will drop to 26.1M65

- Plant will face difficulties to get established65

- cattle supply shortage65

- find competant workers65

- establishment of product in a highly competitive wholesale beef marketplace65

- Maybe AACo plant will survive, others to the south of Australia may not.65

- November. Financial year earnings released. Pre tax earnings for first half of year negative $8.2M mainly due to cattle sales revenue reducing by $50.4M as company held stock to be processed at the abattoir.68

- Since original business case developed has been significant improvement in manufacturing beef prices68

- underpinned by US beef producers rebuilding herds.68

- First customer was an un-named domestic manufacturing customer on the Eastern seaboard70

2015

LIVINGSTONE BEEF FACILITY IS OFFICALLY OPENED 21ST FEBRUARY 201571

- February.Facility is listed on Ausmeat Accreditation list, Establishment #800

- Export abattoir Beef/offal

- Facility is officially opened by Prime Minister Tony Abbott71

- nearest existing abattoir 2,500km from Darwin.71

- Facilities main value will be competitive tension71

- Intend to have a full single shift in operation and killing 520 per day by March 201570

- Jason Strong rejected media statements facility would battle to secure stock, due to competition from live export70

- Live export steers – ex Darwin 275c/kg70

- Heifers – ex Darwin 255c/kg70

- Cows – ex Darwin 170c/kg70

- Note LE cows must be spayed or preg tested empty

- Facility has started exporting beef with a container sent out of Darwin bound for Hong Kong.72

- As the facility ramps up production focus will shift to product export72

- Facility will produce beef products, hides and rendered products for markets across Asia and the US72

- Some cattle had already been purchased from producers72

- Prices to producers/suppliers will be either72

- Over-the-hooks – animals supplied into the plant72

- Live weight delivered likely to Pell Station.72

- April. Pell Airstrip property is being transformed as an integral part of the supply chain for cattle to Livingstone processing facility77

- Large weigh bridge capable of weighing individual trailers of an entire roadtrain.77

- Accommodation block, hay sheds, commodity sheds, yards and office blocks77

- Current purchase structure of abattoir will be to those animals delivered to the abattoir facility to be paid over the hooks77

- Livestock delivered Pell will be paid live-weight on stock delivered.77

- Pell and Labelle Downs will be used to hold animals to gain more weight prior to slaughter or being attached to groups destined for live export.77

- hay for Pell is being sourced from Torilla which AACo also own.77

- NT Environmental Protection Authority (EPA) order AACo to take “immediate action” to solve odour problems coming from the works.78

- Odour is being caused by poor quality of wastewater being used, possible over-used by AACo for irrigation78

- EPA had given permission to AACo to start processing cattle so the system could be tested and fine tuned78

- Maximum cap was place on number of head to slaughter at 250 head a day78

- AACo volunteered this amount78

- AACo had presented a plan to mitigate odours and ensure sustainable compliance with the Environmental limits78

- May. Livingstone facility slaughters 300 head a day for the first time79

- Milestone to the road of full capacity of 500 head per shift79

- First container of beef from the works had landed in th US79

- Past 3 months shipments had gone to Korea, Japan, Hong Kong and Singapore79

- 2014/2015 Annual results are released

- AACo earned $9.6M profit,79

- previous year loss of $39.9M79

- Boxed beef now account for 77% of AACo revenue79

- Processed Beef $277M (includes Livingstone facility)103

- Wagyu beef accounted for 52% of boxed beef revenue104.

- the more boxed beef sold by AACo the better the revenue to them79

- AACo are targeting higher boxed beef turnoff.79

- Processed Beef $277M (includes Livingstone facility)103

- Past 12 months to 31st March 201479

- Cattle sales $120.5M,79

- fallen in the past 12 months $70.5M79

- Boxed beef sales $188.2M79

- Increased in the past 12 months to $267.6M79

- Cattle sales $120.5M,79

- AACo’s current gearing ratio 32.7% at 31/03/201579

- Equity 67.3%

- Debt increased from $225M to $366M103

- Previous gearing at 31/03/2014 23.3%79

- Equity 76.7%

- AACo’s publicly listed status has meant considerable transparency with investors and broader industry and community about the project.80

- Plant has now entered 6 export markets, exported from Darwin via Singapore80

- Facility is licensed to access full range of front-line markets80

- country specific markets like China are not yet included.80

- Initial domestic supply had been due to management of customer relations80

- Early volume predictions of production suited the flexibility of domestic customers80

- Exports require stable output80

- Stability of supply will improve as volumes increase80

- AACo do not need to spend significant investment on large volume osmosis equipment to overcome water quality issues80

- Environmental issues are not constraining processing operations80

- Cattle held on properties for processing are not causing environmental or welfare issues.80

- properties have the capability to hold an entire years processing capabilities with no environmental impact.80

- No outside cattle were contracted for slaughter until March80

- Plant is not cannibalising profits from AACo pastoral operations80

- the whole premise of the Livingstone plant is to provide an alternative market for cattle80

- adding value to cattle that previously had limited market value prospects80

- Some cattle are still live exported if financially attractive80

- Plant will continue to run a single shift for operational reasons not environmental80

- July. Indonesia cuts quota of live cattle imports.50,000 for quarter to Sept 2015.104

- Same period last year had been 250,000 head104.

- AACo AGM. The boxed beef transformation has created a more robust business104.

- making strategic decisions to reduce the number of cattle sold externally104.

- Volume and pricing of boxed beef sales continues to increase105.

- August. AACo publically advertise kills space is available for cows of various weight range for September through to October81

- Prices weighed Pell Airstrip81

- $1.85/kg for cows over 421kg

- $1.75/kg for cows 391kg – 420kg

- $1.50 for cows 340kg – 390kg

- the abattoir is generally processing cattle not suited to Live export markets but is competing with southern processors81

- Midfield Group’s abattoir at Warrnambool Victoria has been buying large number of cull cows and old bulls from the NT81

- prices are very competitive being offered by AAco.81

- Indonesian import permits for slaughter & feeder cattle is still not released81

- NT Environment Protection Authority (NTEPA) continues to receive complaints about “foul odours” coming from the new abattoir82

- Problem is caused by poor quality waste water being used for irrigation82

- NTEPA met with AACo January to discuss odour issues82

- Company made improvements to manage odours and seperately applied to the NT Government to build additional improvements to the facility to specifically manage odours82

- complaints had reduced dramatically

- NTEPA met with AACo again March

- NTEPA believe odours can be eliminated entirely

- Wrote a letter to AACo to improve odour reduction further82

- AACo did do air quality control report, which recommended an odour audit was conducted – audit wasn’t done82

- NTEPA instruct under section 48 Waste Management and Pollution Control Act that the audit be carried out issued in August82

- Conducted by an accredited expert in odour control

- Will involve a thorough check of all buildings

- Community interviews

- How weather affects the odour

- Recommendations

- Which NTEPA want AACo to follow

- Want implementation of improvements by the end of October 2015

- Currently processing 350 head a day83

- September. Currently processing 400 head a day83

- 6-7 cuts from carcasses, as well as mince83.

- Markets in Korea and Japan83

- US market – Mince83

- AACo purchase Thorner Station in QLD – $4.1M83

- Exit Tipperary Station that had been an agistment agreement83

- October. AACo’s shift from cattle producer to vertically integrated beef operation is delivering results83

- increased earnings reflects success of switching from selling cattle to capture value of the herd when converted to beef83

- EBITA for the first half of 2015 financial year (Ending September 2015) $8-$12M83

- Last year same period $8.4M loss

- Beef sales as a percentage of revenue have risen from 47% to 80% year on year

- Branded program – 1824 that is 100day grainfed

- 3 years ago processed 26-27,000 head with only 1500-200 being owned by AACo

- In 2016 processed 60,000 through 1824 and owned 50,000 head of those animals

- AACo have maintained a herd of 170,000 head83

- despite liquidation of females due to drought

- Livingstone abattoir began to process 350 head a day in August increasing up to 400 head a day in September83

- processing 6-7 cuts from the carcases, including mince

- established markets to Korea, Japan and US (Mince)

- processing 6-7 cuts from the carcases, including mince

Source 2015_-_28__aaco_fy16_half_year_financial_report___final

Northern Beef Performance as at 30/09/2015. Pg 11.

- November. Half Year financials AACo report a $97M increase in statutory earnings to $92M and a statutory net profit of $50 for the 6 months84

- $64M improvement on previous years same period84

- First time in 8 years that a first-half profit has occurred106

- “We are selling more kilograms, off the same herd base, for more money” Jason Strong, AACo Managing director82

- Increased throughput at the Livingstone facility comprising of 16% of group meat sales revenue in H1 FY16.82

- Boxed meat – particularly wagyu cuts, surged by 90% to $218M106

- 2 years ago boxed beef represented 47% of total sales, today that stands at 84%106

2016

- February. NT Environmental Protection agency not satisfied with odour audits85

- Suggests some errors in estimates in regards to winds and magnitude of the emissions from the irrigated areas85.

- Local residents are still complaining of odours85

- AACo plan an upgrade to the site to address all concerns85

- March. Livingstone facility is currently processing more than 400 head a day86

- Management were happy with operations through the wet season86

- 2015/2016 being the first full wet season of operation86

- Expectation capacity will increase to 500 day in the coming dry season on full single shift86

- Competition is increasing for cattle86

- Mix of stock coming from AACo’s own stock and other producers86.

- Increasing number of producers are sending stock to Southern works such as Warrnambool86

- Could be traditional markets for those producers86

- Southern facilities need to keep operating, thus source stock further afield86.

- Vietnam live export is also strong competitor86

- Heavy cull cows and some heavy males being exported86

- AACo Annual report to 31/03/2016. Livingstone account for 16% of overall Meat sales84

- 16% = $65,523,000 (Total Meat Sales $428,272,000)96

- AACo Director – Shehan Dissanayake. Is concerned with the disconnect between head office and on the ground staff at properties, is causing the company to underperform.107

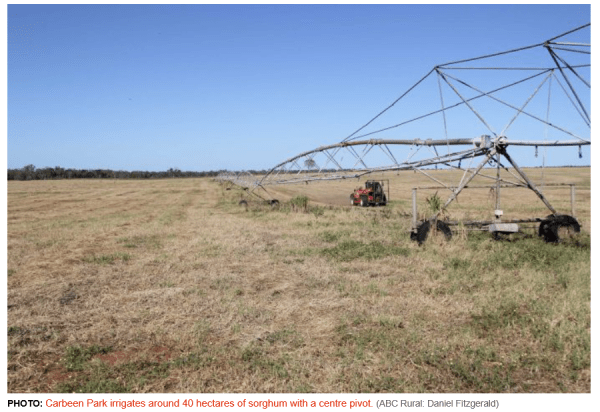

- April. Carbeen Park ( Cattle depot located Katherine and leased by AACo) turns over 40,000 head of cattle in the previous year87

- Cattle are purchased from WA and AACo’s own properties to spell a the site before being trucked to the abattoir at Livingstone87

- Most stock are cull cows and bulls unsuitable for live export87

- Some producers able to sell cattle in small lots that they could never sell before87.

- Carbeen is also a registered export yard able to pre-export stock, then trucked straight to the port for loading87

- Carbeen cuts 400ha dryland sarbi and verano grass with 40ha sorghum under centre pivot87.

Source ABC rural. 21.01.201687.

- AAco Livingstone Beef Processing facility publish 1st Community Newsletter94.

- Livingstone-Beef-Newsletter-April-2016

- Registration to receive updates can be made on AAco website AACo Livingstone Beef Operations

- Livingstone-Beef-Newsletter-April-2016

Source. AACo. Livingstone Beef Operations Newsletter April 2016.

April Newsletter indicating the make-up of the work force at the facility.

Source AACo Website. Livingstone Operations. Accessed April 2017.

- Major share holder in AACo – Tavistock. Managing Director – Shehan Dissanayake.102

- Mr Dissanayake is an AACo Director.102

- September. Producers are sending some stock south to higher paying processors

- 3,000 head have passed through spelling station at Sturt plains in the past 4 months88

- Southern meatworks were paying freight after weighing at Sturt plains.

- 3,000 head have passed through spelling station at Sturt plains in the past 4 months88

- significantly less cattle have been exported live from Darwin this year88

- October. Upgrades are made to the wastewater treatment facilities89.

- Current 12ML capacity will be increased by 25%89

- 4ML increase in the covered anaerobic lagoon89

- Current 12ML capacity will be increased by 25%89

Source ABC Rural 07/10/201689

- Current throughput capacity is 520 animals per shift.89

- Built capacity of the plant was 510-520 head to be processed on a full shift89.

- AACo launch 2 high end beef brands in Singapore89

- “Premium luxury brand”89

- Wylarah brand – Wagyu beef grown in central QLD89

- Joe Lewis converts 59 of 160 convertible Notes into fully paid ordinary shares in AACo.108

- Convertible notes were given a fixed share conversion price of $1.148.108

- significant discount to AACo’s net tangible assets per security of $1.90108

- Was a further $219M non-renounceable entitlement at $1 per share108

- Mr Lewis took up his own full entitlement and underwrote any new share that existing shareholders didn’t take up108

- If other shareholders didn’t take up their offers then Tavistock would buy them108

- Tavistock now have just under 38% stake in AACo. Worth approximately $350M108

- Now two Tavistock directors on the AACo board108

- Convertible notes were given a fixed share conversion price of $1.148.108

- November. Full runs commercial trial processing buffalo90.

- 8 head had been processed previously but additional equipment and training of staff had been required90.

- Equipment was required particularly for the horns90

- Possible one day a month could be allocated to buffalo90

- 8 head had been processed previously but additional equipment and training of staff had been required90.

- Currently employing 200 people90

- Both skilled and unskilled90

- Actively employing local people, require more90.

- Currently processing beef 480-500 head a day90

- equates to 75-80 tonnes of meat per shift90

- AACo announce revenue from meat and live cattle sales has fallen $46M for the 6 months to Sept 30. 201691

- Half year results91

- Net profit $47.9M – down $1.9M same period last year91

- Revenue $214M91

- Underlying earnings improved by $2.4M91

- Live cattle sales down $28M – reflective of more stock being processed through the companies own supply chain91

- Costs have cut 25% to improve earnings in the company91

- Estimated Asian swamp buffalo numbers across the Top end are 150,000 head92

- Majority are located in the Arnhem land92.

- Kakadu National park having 6,500 head92

- Buffalo management is being assessed but will require government support aimed at culling and capturing some stock92

- Majority are located in the Arnhem land92.

- Cost of Production (CoP) $2.77 for every kg of cattle weight added was reduced to $2.09 per kg.109

- Cuts in CoP were due to slashing of transport costs as the business streamlined its alignment of cattle breeding and grazing on properties with specific abattoirs, feedlots and meat brands.109

- Two new beef brands launched – Westholme and Wylara109

- Joe Lewis – Travistock now own 39% of AAco shares.109

2017

- February 10. Livingstone abattoir is temporarily shut down due to lack of stock93 because supply has been affected by heavy monsoonal rain cutting off road access to many properties93 .

- 1st time facility has shut due to bad weather93

- Abattoir is shut down temporarily due to lack of cattle being able to actually be transported into the site.134

- Shortfall caused by heavy monsoonal rain.134

- closure will likely be only 1 week93

- First time facility has shut down due to weather in 18 months of operation134

- 1st time facility has shut due to bad weather93

- A year round operating abattoir was sustainable in the NT93

- AMIEU claims 300 workers will be affected93

- Workers will not receive pay while stood down93 .

- Other facilities in other states have even opened from the Christmas shutdown yet93

- Longer shutdown may occur due to weather93 .

- Jason Strong, AACo CEO still believes it is possible to have a year round abattoir operating through the wet season.134

- “The plan’s still very solid and the execution of it’s still fine….” Jason Strong. AACo CEO134

- Approximately 300 workers were affected by the shutdown134

- Workers will be stood down without pay134

- March. Australian government announce that China will increase market access for chilled meat products133

- Chinese FTA has decreased tariffs133

- Allow the number of meat processors in Australia to increase from 10 to 36133

- 15 were expected to have approvals fast tracked133

- South American countries have been squeezed out of the Chinese frozen market133

- China had banned chilled imports from Australia in 2013 with only 11 facilities being able to regain access.133

- March. AAC_2017_Annual_Report

Source AAC_AACo_2017_Annual_Report

Source AAC_AACo_2017_Annual_Report

- Meat Sales (Including all boxed meat and Livingstone) decreased 11% ($45,236,000) from 31/03/2016112

- Total Meat Sales 31/03/2017 $383,036,000. 31/03/2016 $428,272,000112

- Australia – Increased 15%112

- USA – decreased 33%112

- South Korea – decreased 5%112

- Japan – decreased 57%112

- Other countries – increased 10%112

- Total Meat Sales 31/03/2017 $383,036,000. 31/03/2016 $428,272,000112

Source AAC_AACo_2017_Annual_Report

- Average Value of Stock as at 31/03/2017 $1,207 per head across all stud, breeders, calves, trading and feedlot animals – 662,482 head. (Pg 59)112

- Breeding herd consisting of 540,000 head113

- April. Livingstone hopes to export meat to China.110

- Applied for permission to export to China.110

- Livingstone currently has access to 27 customers.110

- USA being the largest customer.110

- Higher quality beef cuts are mostly sent to Asia110

- Looking at unutilised quota of 2,250 tonnes of frozen buffalo meat that Australia has with the European Union110

- Quota had not been accessed since 2003110

- April 7. Facility is back in full production after it closed a week earlier this year due to lack of cattle in the wet season110

- Key relationship establishment has allowed the abattoir to operate with minimal disruption through the wet season.111

- Processing capacity was maintained at 500 head per day.111

- Only one week shut down in February due to weather affecting access and odd Friday shutdown.111

- Reduced throughput was widely experienced in the processing sector courtesy of trough trading conditions.111

- Facility is halal accredited, Hot boning, or immediate boning after slaughter.111

- Carcase moves through the production line in 45 minutes111

- Livingstone is supplying 90CL or manufacturing meat mostly to United States.111

- Four main markets are supplied111

- Some cuts such as rumps being sold domestically111

- Four main markets are supplied111

- Three trials of buffalo have been run111

- Buffalo meat went into domestic market for pies and buff burgers111

- AACo would like to keep the buffalo production increasing as relationships are established111

- August. Joe Lewis. Tavistock now own 41% of the 193 year old AACo113

- Mr Lewis’s representative Shehan Dissanayake is made a senior executive and key member of the leadership team113

- Dr S Dissanayake owns 2.02M shares of AACo (31/03/2017)112

- Mr Lewis’s representative Shehan Dissanayake is made a senior executive and key member of the leadership team113

- AACo CEO Jason Strong resigns113

- AACo’s share prices plunges 24% in the past year113

- September. AACo Livingstone start to commission a new waste water treatment plant that has recently been installed.114

- Covered anerobic lagoon that captures gas for future use at the plant.114

- Cost $8.7M114

- Will take approximately 3 months to be in full operation.114

Source ‘Darwin’s AACo abattoir commissions water treatment facility…’ ABC Rural. 18.09.2017. Audio

- November. Jessica Rudd, daughter of former Prime Minister Kevin Rudd is appointed as a non-executive director of AACo.116

- December. New CEO – Hugh Killen115

- Experienced in finance – three decades in the banking industry including 15 years with Wespac leading its fixed income, currency and commodities business.115

- Experience in volatile markets having been head of Westpac’s North American business during the global financial crisis.116

- Has a family background in farming but has never run an agricultural operation or acted as a CEO.115

- Mr Killen will receive a fixed annual renumeration $600,000, cash bonus max $300,000 and max $150,000 under AACo’s performance rights plan.116

- Experienced in finance – three decades in the banking industry including 15 years with Wespac leading its fixed income, currency and commodities business.115

2018

- March 17. Cyclone Marcus hits Darwin. Category 2 cyclone with winds up to 130km/hr135

- April. Annoucement is made that AACo was likely to post an underlying statutory loss of between $30M – $40M for the 12 months to March 2018121

- Livingstone beef operations write down of $60-65M121

- Facility is expected to have contributed EBIT & Depreciation and Amortization loss $18-22M ending 31/03/2018117

- Compares to loss of $12.5M ending 31/03/2017117

- Losses reflected ‘Onerous contract provision’ – the abattoir was committed to118

- Gas provision supply contract119

- Deloitte Accounting firm has been engaged to conduct a strategic review process to assess all available options for Livingstone, including improving the operational efficiency of the plant.117

- Update of the review to be provided in the full FY18 results119

- Facility is expected to have contributed EBIT & Depreciation and Amortization loss $18-22M ending 31/03/2018117

- Disclosure of the individual performance of the Livingstone facility had not been done before in reports of financial performance.

- Segment disclosure would be occurring in the coming FY18 results119

- Livingstone beef operations write down of $60-65M121

- Facility currently employs about 200 people117

- Compares to profit $133.2M in the prior year121

- AACo shares have slumped to $1.12121

- Decrease of 31.5% in the last 12 months121

- Second Review of AACo was being conducted121

- Company was not considering selling property121

- Review will focus on process and efficiency within AACo’s supply chains

- “AACo’s performance has been affected by external challenges such as increased competitive dynamics in certain markets, a higher Australian dollar, higher input prices, and an elevated cattle price environment for Livingstone Beef” Mr Hugh Killen, AACo CEO.117

- Recent transition from retaining brand ownership through the supply chain to instead selling cattle is in stark contrast to what previous management teams claimed had pulled AACo out of negative cash flow in the first place.117

- Key Pillar in AACo’s vertical integration had been the opening of the Livingstone abattoir.119

- Increased competitive dynamics had occurred in some of the beef product portfolio’s.119

- Larger exports out of the US and the strength of the Australian dollar119

- Net debt at years end $348M119

- Gearing ratio (Net debt/total equity +net debt) 26%119

- AACo’s stated target net debt 20-35%119

- Debt refinancing had been completed in September 2017125

- Gearing ratio (Net debt/total equity +net debt) 26%119

- May. New Chief Operating officer (Pastoral) – Anna Speer.122

- Currently CEO of online livestock trading company – Auction Plus.122

- Formerly worked for Australian Consolidated Pastoral122

- Ms Speer will be responsible for122

- 16 outback cattle stations in QLD and NT

- 2 feedlots

- Livingstone abattoir

- 500 regional employees and

- more than 500,000 cattle.

- May 23. AACo announces it will suspend operations of its Livingstone abattoir.123

- Facility has commitments through to August.123

- Likely operation will suspended September 30, 2018.123

- Possibly earlier stoppage may occur.123

- Facility has been in operation for 3 years and currently employs 200 people123

- Blend of local workers and overseas 457 visa holders128

- Workers will be offered redundancies128

- Total one-off write down of $74.9M includes123

- $69.5M in respect to buildings, improvements, plant and equipment

- $5.4M onerous contract

- Local pastoralists are concerned old bulls and old cows located on properties now have no where to go123

- “They couldn’t meet the market with the prices they were giving for cattle which is why a lot of people weren’t actually going there” Amanda Murphy, Pastoralist, Kalala Station123

- AACo said its earnings were impacted by a number of factors.123

- increased competition affecting certain parts of product portfolio123

- reduced volume due to less reliance on external supply123

- increased input costs due to dry conditions.123

- High labour costs126

- Labour competition with local gas and mining projects128

- Labour costs were unviable128

- Inputs were just too dear to make a viable profit at the plant130

- Staging of cattle to maintain supply through the wet season created an additional cost burden130

- Potential buyers are welcome to talk to AACo about the future of the Livingstone abattoir.126

- Could be options with other partners126

- Facility had relied on non-AACo herds to provide about 80% of its throughput126

- AACo’s own cattle processed through Livingstone are transferred at observable market rates130

- Livingstone cattle price problems were due to herd reduction that has occurred across large parts of Australia130

- Supply chain inputs were far higher than would be expected in southern beef processing environments – including labour contracts at the abattoir126

- Meat from the Livingstone plant averaged just $4/kg126

- Sold domestically and to China, Korea, Indonesia and Japan126

- Livingstone generated one fifth AACo’s revenue in 17/18126

- Livingstone abattoir has failed to turn a profit since opening in late 2014127

- Abattoir is not officially for sale127

- legitimate offers would be considered127

- If market conditions change the plant could be profitable130

- AACo had miss-matched the objectives of the NT abattoir127

- Abattoir to supply low value hamburger mince to US commodity markets127

- push by AACo’s largest shareholder to become a luxury beef producer127

- AACo denied hanging onto the abattoir as a hedge or calculated bet that the $1.2B northern Australia live cattle export trade might be banned in the near future because of animal welfare or activist campaigns127

- Hugh Killen denied that live cattle export was responsible for the failure of the Livingstone Beef plant127

- Facility will be mothballed with a working crew retained of 12 people129

- Licences and standards will be maintained to allow re-start in a short time if required129

- Abattoir will cost $400,000 per annum to simply maintain in a mothball state129

- Observers say contributing factors to Livingstone predicament are more than just livestock procurement and labour130

- Some point to AACo’s multi layered and generously rewarded management profile130

- Poor operational set-up and strategy at the plant130

- AACo handed over domestic marketing to Australian Wholesale Meats which took $2-3/kg off the margin of sales130

- Some other processors mystified as to why the plant wasn’t setup as a least cost hot boning plant suited to efficient generation of frozen lean grinding beef130

- QLD processor Australian Country Choice (ACC) visited the site to offer guidance on set up and operational strategies.130

- No suggestion ACC has any direct interest in investment or management130

- Broome ‘Yeeda’ WA abattoir is also recently built.131

- Processing 1,100 – 1,200 per week and is making a profit selling generic trim grinding meat for hamburgers131

- Yeeda has been successful due to its simplicity, lack of unnecessary overheads and remained a ‘family show’131

- All product is forward sold

- with majority of each boned carcase going to frozen commodity grinding beef pack

- Relies on older cull cows and bulls not suited to the Live export trade

- Queensland abattoirs advertise in NT papers to encourage meat workers to their facilities.136

- Meatworks around Australia were desperate for skilled workers.136

- Livingstone abattoir had agreed with AMIEU to pay workers $200 a week retention bonus until the facility closes.136

- It will be very difficult to get the facility in operation again if mothballed and staff move away from the area.136

- Some staff had come from interstate to work at the abattoir.136

- Livingstone had been processing stock mostly not suited to the Live export market.136

- Some slaughter animals may be now sold through Live Export.136

- Most will have to be sent to other abattoirs in other states136

- Significant freight costs136

- Likely negative impact on price136

- Abattoir had been processing a lot of horned cattle that were unable to be sold to Live export.136

- June. Former Managing Director – David Farley say’s the abattoir will not stay closed long137

- Was Managing Director 2009-2013137

- Facility can make a comeback and be profitable.137

- Issues exist around labour costs and energy costs were manageable137

- Largest issue was company’s culture and lack of experience in meat processing.137

- Opportunities to continue the abattoir operation will likely come through a joint-venture or other style of operation that complements AACo’s other business operations.137

- Cull cows at Darwin are currently selling $1.70 to $1.85 per kg (Live)137

- A manageable price conversion through the abattoir should be achievable due to the frozen cow 90CL value.137

2019

- July. NTCA meet with Chinese owners of Darwin Port to discuss opportunities to export beef from NT to China.138.

- Landbridge group had already invested in cold-storage facilities at the port and were interested in boxed beef trade between NT and Shandong Province.138.

- Chinese were circling other mothballed abattoirs in the Territory.138.

- NTCA had a vision of “network of meatworks” through the central NT corridor to include.138. –

- Batchelor, (NT)

- Currently undergoing refurbishment with likely operation to begin March 2020.

- Livingstone (NT)

- Currently mothballed and closed due to operational costs

- Wamboden (NT)

- Currently closed and not in operation.

- Batchelor, (NT)

- Chinese investment company commit to construction of new facility – Hughenden (QLD) processing abattoir to begin operating in 2020139.

Source’s for Livingstone Meat Processing facility

-

- Weekly Times, ‘AAco to build NT abattoir’ 06.06.12

- AAco Board letter. 19.10.12 www.aacont.com.au

- Farm Online ‘AAco needs to get serious, says Crean’ 19.10.12

- AAco, North Australian Beef Limited information phamplet. NTCA meeting Dec 2012

- ‘Equity partners in hunt for Darwin Abattoir project’ Beef Central 04.02.13

- ‘AA co’s nod to Darwin Plant’ QLD Country Life 25.10.12

- ‘New northern abattoir still lacks government support’. Katherine Times 10.1012

- ‘Abattoir will ‘not stop Live Ex’ Katherine Times. 10.10.12

- ‘We’re Committed to NT’ QLD Country Life 11.10.12

- Online Comments – Stock Journal 07.06.12

- ‘AAco mulls building top end abattoir…….’The Australian 23.10.10

- ‘Northern abattoirs make their case’ QLD Country life. 24.02.12

- ‘Community update’AAco. 04.02.13

- ‘Darwin abattoir plan on tenterhooks’ ABC rural. 23.04.12

- ‘AAco’s ‘green’ abattoir punt’ The Land. 07.02.12

- ‘AAco blasts 457 fears, FTA lag’ Stock and Land. 18.03.13.

- ‘Work to recommence on Darwin abattoir’ ABC Rural. 22.05.2013.

- ‘Farley Walks… but was he shown the door’ QLD Country Life 08.08.2013.

- ‘AAco may need $150M in fresh equity’ Katherine Times. 14.08.2013.

- ‘Departure of AAco’s CEO to be scrutinised’ QLD Country Life 15.08.2013.

- ‘Darwin plant set for 2014’ Stock Journal 29.08.2013

- ‘Ag company to raise $299M’ Katherine Times 18.09.2013

- ‘Investors stampede AAco’s debt offer’ Stock Journal 26.09.2013

- ‘Lewis takes another slice’ Nth QLD Register. 31.10.2013

- ‘AAco: $27.1M Northern buy-up’ Nth QLD Register 31.10.2013

- ‘AAco suffers $31.6M loss’ QLD Country Life 14.11.2013

- ‘AAco reports $31.6M Net loss’ Nth QLD Register 14.11.2013

- ‘AAco confirms $90M Northern abattoir will be built’ ABC News 22.08.2013

- ‘NZ company signed to build Darwin killing floor’ ABC Rural. 02.10.2013

- ‘NT Government defends plan to put prisoners to work in abattoir’ ABC News. 04.01.2014

- ‘Concerns over psychological impact of abattoir work on NT prisoners’ ABC Rural. 06.01.2014

- http://www.flinders.edu.au

- http://www.mindinganimals.com

- http://www.nzchas.canterbury.ac.nz

- ‘AAco to build abattoir’ Weekly Times 06.06.2012

- ‘AAco Board approves construction of Northern Territory meat processing facility’ AAco media release 19.10.2012

- ‘Darwin meat processing facility’ AAco Community update 12.12.2013

- ‘Kimberley pastoralists cautious over proposed Darwin abattoir’ ABC Rural 27.07.2010

- ‘AAco feeling export ban pain’ Stock and Land. 15.03.2013

- ‘Doubts mount about Darwin abattoir’ ABC Rural 19.04.2013

- ‘No room in CLP Budget for abattoir’ NT Country Hour. 26.04.2013

- ‘AAco rules out split, plans $299 raising to expand in Asia’ The Australian 13.09.2013

- ‘The economic impact of the proposed AAco abattoir’ ACIL Tasman. May 2012

PDF file for report located 2012 – May. - ‘Strong new AAco chief’ Stock & Land 24.01.14.

- ‘Organic farmers seek Darwin abattoir waste’ NT Country hour. 25.02.14

- ‘Darwin abattoir on track for AAco’ ABC Rural. 20.02.14

- ‘Abattoir to operate in September’ Katherine Times 02.04.14

- AAco Northern Beef Processing facility, handout 27.03.2014

- ‘AAco needs to get serious, says Crean’ The Land. 19.10.2012

- ‘AACo set for spring start’ The Land. 28.03.14

- ‘AACo starts recruiting process for Darwin plant’s September start’ Beef Central 08.04.2014

- ‘AACo showcases Darwin product to the market’ Beef Central 30.05.2014

- ‘Abattoir drives AACo plan’ QLD Country life 28.07.2011

- ‘Restrictions prompt AACo abattoir plan’ The Land 16.08.2010

- ‘AACo’s Asian Future’ QLD Country Life 07.08.2014

- ‘AACo sheds light on ‘preferred supplier’ status for Darwin plant’ Beef Central 22.08.14

- ‘Thousands of head return to majestic NT cattle station following purchase by AACo’ ABC Rural 02.09.14

- ‘AACo abattoir looks to advanced refrigeration system ahead of September opening’ ABC Rural. 11.09.14

- ‘NT abattoir ready to roll’ Farmonline. 22.09.14

- ‘Head of Australian beef company describes NT abattoir venture as ‘frustrating’ process’ ABC rural. 02.10.14

- ‘AACo plant to ramp up to full single shift by March 2015’ Beef Central. 02.10.14

- ‘Australian Agriculture Company jumps final hurdle to gain environmental approval for long-awaited Darwin abattoir’ ABC Rural. 31.10.14

- ‘AACo starts recruiting process for Darwin plant’s September commissioning’ Beef Central 28.03.14

- ‘New Era for northern Australia as AACo flicks the switch on Darwin beef plant’ Beef Central 31.10.14

- ‘Kay’s Cuts: AACo & Iowa beef plant dreams become reality’ Beef Central. 06.11.14.

- ‘Reversing the loss of Australia’s meatworks’ QLD Country Life. 07.11.14

- ‘Cattle head to AACo stations as Darwin abattoir prepares to open’ ABC rural. 18.06.2014

- ‘AACo logs $13.6M net loss for first half’ Beef Central 19.11.2014

- Australian Agricultural Company Limited – Annual report 2014.

- ‘PM opens AACo’s trail blazing Darwin beef plant tomorrow’ Beef Central 20.02.2015

- ‘PM opens AACo NT abattoir’ QLD Country Life 21.02.2015

- ‘Beef From AACo’s new abattoir in the NT exported to Hong Kong’ ABC Rural 23.02.2015

- ‘Ausmeat Accreditation Listing’ as at 10/05/2015.

- ‘Harsh weather conditions affect AACo profits’ ABC rural. 28.05.2014.

- ‘Prisoners help build new Top End abattoir’ ABC News 25.08.2014

- ‘AACo’s Darwin abbatoir sweats on licence….’ ABC Rural 25.09.2014

- ‘The Transformation of Pell…’ ABC Rural 07.04.2015

- ‘New abattoir near Darwin on the nose’ ABC Rural 09.04.2015

- ‘AACo lifts profit by $49.5M’ www.farmonline.com.au 13.05.2015

- ‘Unravelling seven misunderstandings….’ Beef Central 13.05.2015

- ‘AAco looking for Northern Slaughter cows..’ ABC Rural 18.08.2015

- ‘Ongoing odour problems for new AACo abattoir…’ ABC Rural 21.08.2015

- ‘AACo Earnings Turnaround’ www.farmonline.com.au 21.10.2015

- ‘Supply chain focus delivering strong …..’ Beef Central 25.11.2015

- ‘Environmental Protection Authority not satisfied with AACo’s audit….’ ABC Rural 09.02.2016

- ‘AACo abattoir near Darwin processing more than 400….’ ABC Rural 20.03.2016

- ‘Busy times for one of Katherine’s smallest cattle……’ ABC Rural 21.04.2016

- ‘Strong competition from meat processors ….’ ABC Rural 08.09.2016

- ‘AACo expands wastewater handling capacity at Darwin….’ ABC Rural 07.10.2016

- ‘NT abattoir runs first full commercial buffalo slaughter trial’ ABC Rural 11.11.2016

- ‘AACo cuts cost by 25%, as revenue falls’ ABC Rural 23.11.2016

- ‘Researcher calls for Top End Buffalo cull and muster….’ ABC Rural 25.11.2016

- ‘AACo temporarily shuts down Livingstone abattoir near Darwin after heavy rain’ ABC Rural 13.02.2017

- AACo Livingstone Beef Operations

- ‘North sees direct competitive price tension between processors and live – ex’ Beef Central 12.08.2015

- AAC_2016_AACo_Annual_Report

- ‘AACo capital raising progress’ www.farmweekly.com.au 11.10.2013

- ‘Cattle slump hits AACo’ www.farmweekly.com.au 07.11.2013

- ‘AACo chief defends Lewis’ www.farmweekly.com.au 08.11.2013

- ‘AACo the latest target for hotshot Joe Lewis’ Financial Review 25.10.2013

- http://www.abc.net.au/news/rural/2015-07-29/aaco-undergoes-transformation-from-cattle-company/6654102

- https://www.theaustralian.com.au/business/in-depth/global-food-forum/tavistock-md-urges-australians-to-invest-in-agriculture/news-story/53c9131a820d3fab877dc0cab7def62c

- ‘AACo boxed beef profits up as transformation continues’ The Australian 14.05.2015

- https://www.theaustralian.com.au/business/business-spectator/aaco-upbeat-on-indon-cattle-cuts/news-story/987b0df66c6fcd2dd0a349cea915812a

- ‘AACo an long-term buy after move to packaged beef’ The Australian 17.07.2015

- ‘Beefed-up AACo finds its profits in the box’ The Australian 26.11.2015

- ‘Shehan Dissanayake’s unforgettable trip….’ The Australian 26.03.2016

- ‘AACo, the other landholder taken by foreign investors’ Financial Review 30.10.2016

- ‘AACo’s Jason Strong cuts costs for solid profit’ The Australian 24.11.2016

- ‘Top End Abattoir applies to access Chinese…..’ ABC Rural 07.04.2017

- ‘Livingstone broadens its horizons’ www.farmonline.com.au 23.04.2017

- AAC_AACo_2017_Annual_Report

- ‘CEO quits in AACo power struggle’ The Australian 12.08.2017

- ‘Darwin’s AACo abattoir commissions water treatment facility…’ ABC Rural. 18.09.2017. Audio

- ‘AACo appoints ex-Westpac executive Hugh Killen as CEO’ Financial Review 20.12.2017

- ‘Banker Hugh Killen is AACo’s new chief executive’ The Australian 20.12.2017

- ‘AACo reviewing abattoir and beef business…’ ABC Rural 04.04.2018

- ‘AACo abattoir and beef business model under review….’ www.farmonline.com.au 04.04.2018

- ‘AACo to review processing, brand operations….’ Beef Central 04.04.2018

- ‘Opinion: The reality of our northern cattle industry belies popular rhetoric’ Beef Central 29.04.2018

- ‘AACo won’t consider selling farm,cattle’ Financial Review 04.04.2018

- ‘AACo appoints Anna Speer to steer paddock-to-plate beef supply chain’ The Australian 22.05.2018

- http://www.abc.net.au/news/rural/2018-05-23/aaco-closes-livingstone-beef-abattoir-near-darwin/9790454

- http://www.abc.net.au/radio/programs/nt-country-hour/hugh-killen-aaco-decision-to-mothball-abattoir/9791264

- ‘AACo suspends operations at loss-making Livingstone Beef plant’ Beef Central 23.05.2018

- https://www.farmonline.com.au/story/5424766/loss-making-livingstone-abattoir-not-for-sale/?cs=5373

- https://www.theaustralian.com.au/business/companies/aaco-closes-livingstone-beef-meatworks/news-story/c8f4d422cbc8f77510aaa791a6bd6f1b

- https://www.theaustralian.com.au/business/companies/aaco-swings-to-heavy-loss-as-it-battles-dry-weather-conditions/news-story/fbbc972f0f4d03509127c947b4bbb310

- http://www.abc.net.au/radio/programs/nt-country-hour/abattoir-job-losses-a-blow-for-darwins-rural-area/9796498

- ‘High cattle prices, input costs blamed for AACo’s Livingstone plant losses’ Beef Central 24.05.2018

- ‘Kimberley’s thriving Yeeda beef processing venture contrasts with Livingstone’s struggles’ Beef Central 25.05.2018

- ‘AACo shutting down Darwin meatworks to stop financial bleeding’ Financial Review 23.05.2018

- ‘AACo, temporarily shuts down Livingstone…..’ ABC Rural 13.02.2017

- ‘Tropical cyclone Marcus warning’ ABC news 17.03.2018

- ‘QLD abattoirs swoop, as AACo meatworkers in Darwin weigh up their future’ ABC Rural 31.05.2018

- Drwin abattoir will work with right culture and commitment….’ ABC Rural 29.06.2018

- ‘Landbridge Group and NT Cattlemen….’ ABC.net.au

- ‘Chinese investors back major new meatworks for Nth QLD’ 29.07.2019.

Tagged: AAco abattoir, Abattoir history, Abattoirs in Australia, Australian Abattoirs, Australian agriucultural company abattoir, Australian meat processing, Australian meat processing facilities, beef processing facility, cattle station, cattle stations, Darwin abattoir, Darwin abattoir being built, Darwin meat processing plant, Live export, Livingstone abattoir, Meat processing, Proposed Darwin abattoir

Leave a Reply